The craft brewing industry, born from a passion for unique flavors and artisanal techniques, has always balanced tradition with innovation. While the heart of brewing remains in the hands of skilled brewers, the brain of the operation is increasingly being empowered by technology. The Internet of Things (IoT) and remote monitoring are no longer futuristic concepts; they are transformative tools allowing breweries of all sizes to brew smarter, increase efficiency, and maintain consistent quality, even from miles away.

The Brewing Floor, Digitally Connected

At its core, IoT refers to a network of physical objects—in this case, brewing equipment—embedded with sensors, software, and other technologies that connect and exchange data over the internet. Imagine your fermenters, bright tanks, chillers, and even your cleaning systems, all communicating real-time data to a central hub, accessible from your smartphone, tablet, or laptop. This isn’t just about convenience; it’s about unparalleled insight and control.

Why Remote Monitoring and IoT are a Game Changer for Brewers:

- Unwavering Quality Control: The consistency of your beer is paramount to your brand’s reputation. Fluctuations in temperature, pressure, pH, and specific gravity can lead to off-flavors, spoiled batches, and ultimately, lost revenue. IoT sensors provide continuous, real-time data on these critical parameters. Instead of manual checks that are time-consuming and prone to human error, brewers can see precise readings around the clock. This allows for immediate adjustments, ensuring each batch adheres perfectly to the recipe and maintains the desired quality profile. For example, a sudden temperature spike in a fermentation tank can be detected and corrected instantly, preventing the yeast from producing undesirable compounds.

- Optimized Efficiency and Resource Management: Brewing is a resource-intensive process, consuming significant amounts of water, energy, and raw materials. Remote monitoring and IoT enable brewers to meticulously track and optimize these inputs.

- Energy Savings: Sensors can monitor energy consumption across different stages (mashing, boiling, chilling) and identify inefficiencies. Automated systems can then adjust power output for pumps, motors, and heating elements, leading to substantial reductions in electricity or gas usage.

- Water Conservation: Tracking water flow and usage during cleaning-in-place (CIP) cycles or cooling processes helps identify areas of waste. Smart systems can optimize rinse times and water temperatures, contributing to a more sustainable operation and lower utility bills.

- Raw Material Optimization: Precise monitoring of density and sugar levels during fermentation can help brewers determine the exact moment fermentation is complete, preventing over or under-fermentation and optimizing the yield from ingredients.

- Predictive Maintenance: Minimizing Downtime: Equipment breakdowns are a brewer’s nightmare. A malfunctioning pump, a leaky valve, or a chiller failure can bring production to a screeching halt, costing time, money, and potentially an entire batch of beer. IoT takes maintenance from reactive to proactive. Sensors can monitor vibrations, motor performance, and temperature anomalies in equipment, detecting subtle changes that indicate impending failure. This data feeds into predictive analytics, allowing brewers to schedule maintenance before a breakdown occurs. Imagine receiving an alert that a pump bearing is showing signs of wear, giving you time to order the part and schedule replacement during off-hours, rather than facing an emergency repair in the middle of a brew day.

- Flexibility and Freedom for Brewers: One of the most significant benefits of remote monitoring is the freedom it offers. Brewers are no longer tethered to the brewhouse. Whether they’re attending a trade show, enjoying a rare day off, or simply in another part of the facility, they can access vital brewing data from anywhere with an internet connection. This remote access allows for:

- Increased Responsiveness: Address issues promptly, even when not on-site.

- Better Work-Life Balance: Reduce the need for constant physical presence, especially during long fermentation cycles.

- Multi-Location Management: For breweries with multiple sites, a centralized remote monitoring system offers a unified view of all operations, ensuring consistency across the board.

- Data-Driven Decision Making: Beyond real-time alerts, IoT systems generate a wealth of historical data. This data can be analyzed to identify long-term trends, optimize recipes, troubleshoot recurring issues, and inform strategic decisions. Brewers can use this information to fine-tune processes, develop new beer styles, and even predict consumer preferences.

EZBrew: Brewing Automation with Remote Intelligence

The promise of remote monitoring and IoT is compelling, but for many breweries, especially those looking for simplicity and efficiency, the implementation can seem daunting. This is where solutions like EZBrew step in, offering a comprehensive, automated brewing system that inherently integrates remote monitoring capabilities, simplifying the process from start to finish.

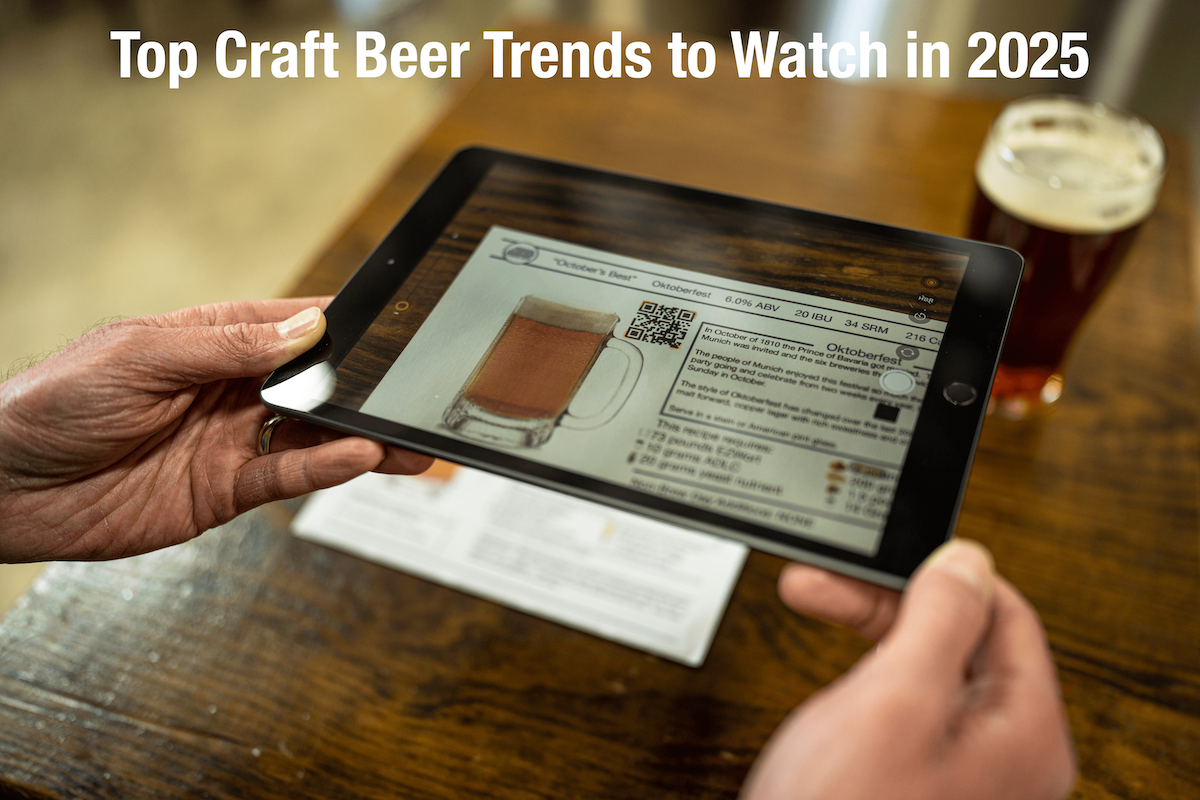

EZBrew systems are designed with a focus on automation and ease of use, making craft brewing accessible even without extensive prior experience. A key component of their offering is the seamless integration of remote monitoring. When a brewery installs an EZBrew system, the connected iPad, which serves as the intuitive control interface, links directly to the EZBrew central monitoring system. This allows for:

- Fermentation Tracking: EZBrew’s remote monitoring provides real-time updates on crucial fermentation parameters like temperature. This means brewers can track the progress of their brew from anywhere, receiving alerts if conditions deviate from the desired range.

- Process Oversight: Beyond fermentation, the system monitors other key stages, ensuring optimal conditions for mixing, chilling, and carbonation.

- Expert Support: By connecting to the EZBrew headquarters in North Carolina, their team can remotely monitor the brewing process. This provides an invaluable layer of support, allowing EZBrew specialists to offer guidance, troubleshoot potential issues, and help ensure consistent quality for their customers. This direct connection bridges the gap between sophisticated brewing technology and accessible operation.

- User-Friendly Interface: The data is presented through a user-friendly app on the iPad, making it easy for brewers to understand complex information at a glance, without needing to be IT experts.

By combining fully automated brewing with integrated remote monitoring, EZBrew allows brewpubs and venues to produce high-quality craft beer on-site with minimal labor and a high degree of consistency. This fusion of smart technology and brewing craftsmanship not only streamlines operations but also provides the peace of mind that comes with knowing your brew is always under a watchful, intelligent eye.

The Future is Connected

The integration of remote monitoring and IoT is rapidly becoming an essential component of modern brewing. From enhancing quality control and optimizing resource use to enabling predictive maintenance and offering unparalleled flexibility, these technologies are empowering brewers to elevate their craft. For those seeking a streamlined, intelligent approach to brewing, systems like EZBrew demonstrate how cutting-edge technology can integrate seamlessly, ensuring that brewing smarter, not harder, is a reality for breweries of all sizes. The future of brewing is not just about the art of the beer, but the intelligence of the process.